EKOLAK PE/P SEMI GLOSS

semi-gloss (PE/P-01-3-xxxxx),

semi-matt (PE/P-01-4-xxxxx),

matt (PE/P-01-5-xxxxx) and

high gloss with average mechanical properties (PE/P-02-1-xxxx, PE/P-03-1-xxxx, PE/P-04-1-xxxx)

General information:

- Base: binding on the basis of saturated polyester resins, specially selected according to their resistance to the effects of weather and UV radiation.

- Colour shade: according to RAL-card or according to the sample.

- Packaging: 25 kg cartons or big-bags of 500 kg.

Powder properties:

- Density (DIN 55 990/3): 1,2 to 1,7 g/cm3, depending upon the shade.

- Yield: 9,8 to 13,8 m2/kg at coat thickness of 60µm, depending on the shade.

- Granulation (Malvern particle sizer): above 40µm…….. 40-55%

- Method of application: traditional CORONA procedure, negative voltage 30-100 kV, possible supply of powder adequate for TRIBO system of application (mark T i.e. PE/P-01-3-XXXXXT).

- Stoving conditions: 190 °C/10 min, object temperature for matt, semi-matt and semi-gloss quality, and 180 °C/10 min for high gloss quality.

- Storage time: 12 months at the temperature below 25˙°C for standard coatings.

Mechanical and technological features of the Polyester/HAA Ekolak:

To determine its mechanical properties the Ekolak was applied to the 0,6 mm thick cold-rolled metal sheet degreased with acetone, and stoved in the oven at the temperature of 190 °C for 10 min, i.e. it was submitted to the conditions, required for the particular type of the Ekolak.

- Coat thickness: 55-80 µm

- Gloss (DIN 67 530, ISO 2813): 10-90 % at the angle of 60°

- Hardness on Bucholz scale (DIN 53 153): minimum 91

- T-bend: minimum T2-OK/OK

- Impact test (DIN 55 669): direct: minimum 50 cm x kg

indirect: minimum 50 cm x kg - Adhesion (DIN 53 151): Gt 0

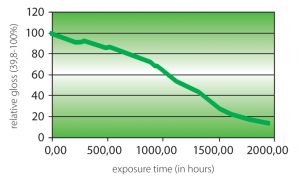

Resistance to the weather conditions – accelerated aging, QUV test; Test conditions:

cycle – 8h UV at 60 °C + 4h 100% humidity at 40 °C, used bulbs UV A 340 (340 nm).

Changes in the gloss intensity in dependance to the accelerated aging is shown in the following chart:

These instructions are the result of years of research and testing in our laboratories. We may not assume responsibility for the results of your work due to the different methods of work and application of different materials. We reserve the right to any alterations and improvements we may find appropriate.